AutoTrickler V4

Since the original AutoTrickler was invented in 2016, it has become the go-to solution for long range shooters who need to measure accurate powder charges quickly.

While the core concept of precisely dispensing onto a lab quality balance has never changed, the mechanical design has constantly improved with two versions of the AutoThrow, Bluetooth support, any many part revisions as a result of new ideas, new processes, and user feedback.

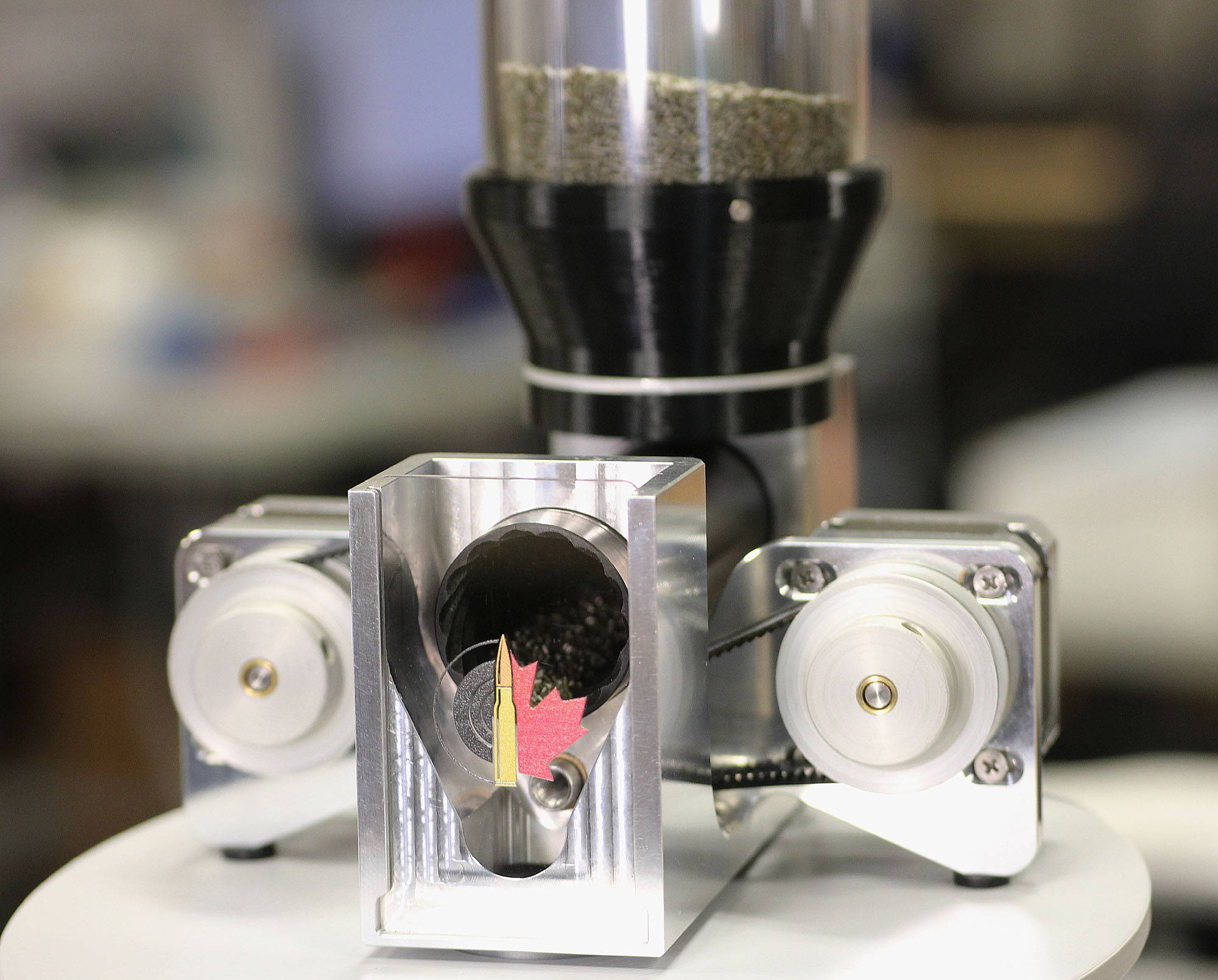

AutoTrickler V4 is a clean slate redesign. Starting with the idea of a single assembly without needing manual adjustments, we looked at every part, every feature, every detail, and built exactly what the AutoTrickler should be.

- Works with fine ball powders like CFE223 and H335

- Works with large kernel powders like N570 and H50BMG

- Maximum flow rate ~50 GN/s for large caliber rifle

- Integrated electronics and motors with fixed cabling

- Acrylic panel and silicone pads ensure assembly is stable, quiet, and level

- All commonly replaced wear parts from previous versions no longer exist

- Potential for performance improvements through app updates

- Integrates with standard A&D FX or FZ 120i, 200i, 300i, or 500i

The AutoTrickler rests on a clear acrylic panel with soft silicone pads that minimize vibration and noise. The housing can be easily lifted from the panel without disturbing the scale. Silicone pads added to the scale platform keep the entire assembly stable and level.

A tilt adjustment within the housing will be factory set. Leveling the scale using its built-in bubble level will set the AutoTrickler at the correct tilt angle.

A speed setting within the Bluetooth app will allow a tradeoff between speed and precision based on user preference. Firmware configurability through the app will allow performance options to improve through software updates in the future.

The hopper incorporates a rotating valve so it can be removed easily. The hopper has a flat bottom so it can rest on a table while holding powder.

When in use, the hopper is positively locked into the housing. The hopper also blocks the powder reservoir from opening while the valve is open, so the potential for a spill is low.

To empty powder, first turn and remove the hopper. Then slide up the window and pour the powder into the hopper. Tilt the unit backwards to clear powder out of the tubes. Any remaining powder will be clearly visible either in the rear reservoir or by looking through the tubes.

Sounds great, how can I get one?

You can place an order for AutoTrickler V4 now. Payment in advance is optional. The schedule is posted on the product page (click this button below).

Regarding other types of scales: V4 requires an A&D FX or FZ model balance. V4 is designed to be placed at a specific height, and expects a fast dynamic response from the scale. The precision and speed of the A&D FX-120i scale is what makes it the best option for integrating with a powder dispensing system and the AutoTrickler is designed specifically for it. Even if you have another high quality balance already, we strongly recommend purchasing the A&D scale and dedicating it for use with V4 as a complete system.